Split bearings refer to parts designed and produced on the basis of integral bearings through a special process. Split bearings are suitable for many fields, such as: large-scale conveying equipment, co-casting roll supports, elevators and conveyors, paper machinery and other industrial fields. Installation is also very important for the use of split bearings. In order to allow everyone to better install the split bearings, the following Zhongyu Bearing Network abbreviation (Huazhou Network) shares the installation steps of split bearings with pictures.

1. Install the bearing base

Install the bearing base or the lower half of the flange in the desired position. If the bearing seat needs to be accurately positioned, it can be bolted to its position. Usually to accurately position the shaft, the bearing base may need to be moved slightly in subsequent installation steps.

2. Install the inner ring

Gently apply engine oil to the shaft, and then wipe off excess engine oil with a dry cloth. Install the inner ring in the correct position on the shaft. Place a soft sticker or feeler gauge on the seam of the two inner halves, making sure that the gap between the two seams is approximately the same. The inner ring of the free-end bearing is usually installed in the center of the outer ring, but there is a special case in which the free-end bearing allows a little axial offset. (In this case, the maximum offset is usually 10% of the roller length, but special types of bearings have larger offsets.)

3. Install the clamping ring

When installing the clamping ring, the joint of the clamping ring and the joint of the inner ring should form an angle of about 90° (the large bearing has 4 clamping rings, and the angle is 45°). Then tighten all bolts on the clamping ring. Use a soft hammer to tap each piece of the inner ring and clamping ring on the shaft, or place a wooden block between the steel hammer and the bearing parts to beat. Tighten the clamping ring bolts again. Repeat this action until the bolts are completely tightened. Check the seams of the two inner rings, the gap should be approximately equal.

4. Install the cage and roller

Apply grease to the cage and rollers, and lightly apply grease to the surface of the inner ring (installed on the shaft) as a protection. Install the cage (together with the rollers) on the inner ring. The two cage halves are snapped together, and the different ways depend on the size and bearing series.

5. Installation of bearing box and outer ring

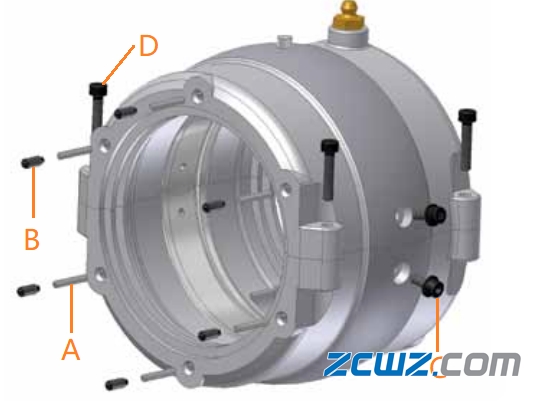

Install half of the outer ring with lubrication holes in the upper half of the bearing box, and the other half of the outer ring in the lower half of the bearing box. Make sure that the end faces of the outer ring protruding from the bearing housing match. All outer rings with ribs must be clamped axially. The lateral positioning bolt "A" can be installed on all fixed end bearing housings. The side ejector "B" can only be installed on some models. The radial bolt "C" and washer can only be installed on the bearing housing of the fixed end and free end large bearings.

Free end bearing box:

Put the radial bolt "C" together with the washer into the corresponding hole of the outer ring, but do not tighten it. Put the two halves of the bearing housing together with the outer ring, and fully tighten the connecting bolt "D". Fully tighten the radial bolt "C". Bearing housing with flanged outer ring (fixed and special models): Put the radial bolt "C" together with the washer into the corresponding hole of the outer ring, but do not tighten it. Put the two halves of the bearing housing together with the outer ring, and fully tighten the connecting bolt "D". Put in the lateral top rod "B" (installation position) and the lateral positioning bolt "A". Then fully tighten the lateral positioning bolt "A" and the radial bolt "C" (installation position). All types: Fill the oil circuit with grease. Loosen the connecting bolt "D" and separate the bearing housing, taking care that the outer ring does not slip out of the respective half of the bearing housing.

6. Install the sealing ring

If installing a three-layer aluminum seal ring, the installation steps are as follows: separate the three-layer aluminum seal ring by pulling out two pins. Lubricate the "O" ring in the hole. Reinstall the "O" ring on the shaft and reinsert the pin. Note: Once installed, the three-layer aluminum seal ring can slide along the shaft. The felt ring seal should be soaked in lubricating oil before being installed in the groove at the end of the bearing housing. Other seal types such as three-layer ring seals must be installed in the groove at the end of the bearing box before installing the bearing box.

7. Apply grease

Apply grease to the inside of the bearing housing, cage, rollers and all seals. For the rotation speed exceeding 150,000mm dn (shaft diameter in mm × shaft speed in rpm), approximately 40% of the grease should be applied to the bearing part, and the rest should be applied to the bearing housing. In this way, excessive agitation of excessive grease can be avoided during high-speed operation.

8. Paint the bearing box up and down

Apply grease to the lower part of the bearing housing. Place the lower part of the bearing housing on the top of the bearing and rotate it 180° to slide it into the lower part of the bearing housing. Place the upper part of the bearing box on top of the lower part, fasten the bearing box and fully tighten the connecting bolts. Apply grease to the ball of the bearing housing.

9. Installation of bearing seat

Tighten the bolts of the base or the lower half of the flange at the installation position. Install the top cover of the bearing housing or the upper part of the flange. If for safety reasons, the shaft can run for a period of time before the bearing housing connecting bolts are fully tightened, so that the bearings can be accurately calibrated. Fully tighten the connecting bolts.

2024-08-07