Radial clearance in gas foil bearings is a complex concept compared to rigid gas bearings and plain bearings. When the rotational speed of the rotating shaft in the foil bearing is zero, there is no clear radial gap between the top foil and the rotating shaft surface due to the forming accuracy and partial area springback of the top foil and the corrugated foil. At the same time, since the top foil, corrugated foil and bearing sleeve of the foil bearing cannot be completely fitted during actual assembly, the theoretical radial gap in the bearing disappears, and there is a preload on the top foil and the surface of the rotating shaft.

Fig.1 Hysteresis curve of radial bearing

The actual radial clearance in the gas foil bearing can be obtained from the hysteresis curve and the structural stiffness curve measured by the static cyclic load experiment. The hysteresis curve of the foil bearing is shown in Figure 1. In Fig. 1, when the deformation displacement increases from zero, the static load starts to grow slowly with the deformation, and the change is basically linear. When the deformation displacement reaches a certain value, the static load of the bearing begins to increase rapidly with the change of displacement, and there is an obvious jump phenomenon. This is because when the displacement is small, the shaft only needs to overcome the gap between the springback deformation of the top foil and the squeezed bearing structure, so the required static force is small. When the displacement is large, the shaft begins to squeeze the bearing elastic support structure, and the required The force starts to increase rapidly.

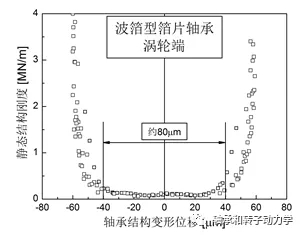

Fig.2 Rigidity curve of radial bearing

The structural stiffness curve of the bearing obtained from the hysteresis curve is shown in Figure 2. The structural stiffness is calculated from the derivative of the load and displacement of the bearing at each deformation displacement. When the unilateral deformation displacement is less than 40 μm, there is an obvious low stiffness region in the stiffness curve, and the stiffness in this region is less than 0.2 MN/m. The stiffness increases rapidly when the bearing deformation displacement exceeds this region, reaching 2.9 MN/m when the deformation is 58 μm. The low stiffness region of the structural stiffness curve is considered to be the true radial clearance of the bearing. According to the analysis results, the single-sided radial clearance measurement result of the foil bearing is about 40 microns. Through this method, the true value of the radial clearance of the foil bearing can be measured relatively accurately.

(Source: Public Account "Bearing and Rotor Dynamics")

2024-08-07